The SeparIX process is an especially robust procedure for the external regeneration of ultrapure mixed bed resins used for condensate cleaning in power plants.

Overview

BENEFITS

- in contrast to prior solutions SeparIX needs no sensors to detect resin types

- no additional chemicals needed for separation of cation and anion resins

- the high purity of the regenerated resins allows operation in ammonium cycle at maximum plant availability

- robust mechanic process with high availability and low maintenance requirements

- simple displacement of operational resin loss through resin hopper of interface resin vessel

- simple construction of separation vessel, similar to conventional mixed bed ion exchangers with internal regeneration

Highest resin purity

The high purity of the regenerated resins allows a use in ammonium cycle.

Applications

Technical data

- Cross contamination of resins: < 0,1%

- Leakage:

- < 1 ppb Sodium

- < 1 ppb Chloride

SeparIX Procedure

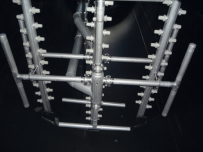

The SeparIX procedure is based on merely mechanic characteristics of the resins. Specially developed collectors separate both resin layers from the border layer.

This prevents blending and therefore a contamination of both resin types.

SeparIX consists of two vessels for resin separation and regeneration as well as a third vessel for interim storage of the interface resin.

1. Pre-regeneration in separation vessel

The exhausted mixed bed resins are pre-regenerated to achieve constant resin layer heights in the separation vessel, independent from their grade of exhaustion. Only after regeneration are resins separated.This process eliminates the need for costly sensors or specialty chemicals to identify and separate resin types.

2. Separation of anion resin, interface zone and cation resin

The anion resin on top of the interface zone is transferred to the anion regeneration vessel.

The interface zone in between the anion and cation resins is then withdrawn from the separation vessel and stored temporarily in the interface resin vessel to be re-used in the following regeneration cycle.

This procedure eliminates the main source of resin cross contamination.

3. Blending and return transport of regenerated, ultrapure resins

The regenerated cation resin is conveyed to the anion regeneration vessel and after subsequent mixing of both resin types the regenerated batch is ready to be transferred back to the mixed bed ion exchangers.

The highly efficient transfer from the regeneration vessel back to the service vessel ensures the high purity of the next batch.

SIMPLE UPGRADE

SeparIX can easily be retroftted to existing condensate polishing plants.

Minimised downtime

A reserve resin amount can be stored in the SeparIX module. This reduces the downtime of the condensate treatment to the time that is needed for the resin transport between SeparIX and the mixed bed ion exchangers.