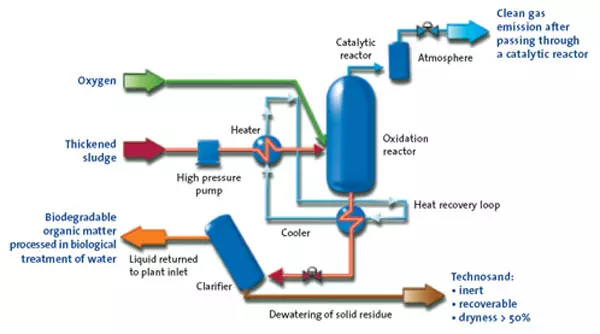

Athos™ is a sludge Hydro-Thermal Oxidation (HTO) process, which turns organic sludge with low dry matter into an essentially solid mineral.

Overview

Athos™ is an innovative process, which combined with anaerobic digestion, enables sludge removal while producing a renewable energy source: biogas.

Athos™ generates 3 stable and/or recyclable by-products:

- clean gas

- organic liquid biodegradable by traditional water treatment

- mineral-based inert solid

Features & Benefits

The Athos™ process complies with all regulations on the disposal of wastewater treatment sludge whilst remaining cost-effective. It benefits from the technological expertise and track-records of the Veolia Group, the world leader in municipal and industrial water treatment.

An environmentally friendly process

Athos™ is a clean technology: all the sludge components are recycled, recovered or discharged to the natural environment with no adverse effects.

- Final result: a concentrate of mineral matter accounting for only 1% to 2% of the quantity of initial liquid sludge;

- Possibility of recycling the technosand for building materials;

- Stabilization of the heavy metals in the solid residue in a non-leachable form (inert waste);

- Zero emission of polluted gases nor harmful by-products (nitrogen oxides, dioxins, furans);

- Reduction of greenhouse gas emission (50% drop in CO2 emissions compared with incineration;

- Destruction of toxic, malodorous (Hydrogen sulfide, mercaptan, etc.) and organic trace substances.

A cost-effective thermal process

Operating costs are reduced by:

- Moderate operating conditions (temperature and pressure, limited O2 consumption);

- Reducing the dewatering stage. The dewatering of oxidation residual doesn't require reagents and reaches 50% of dryness.

A flexible process

Athos™ provides high operational flexibility:

- Treats all types of thickened sludge (7 to 8% of DS);

- Possibility of adjusting retention time, temperature and oxygen flow, in accordance with sludge composition;

- Equipped with advanced automation.

A compact process

Thanks to its compact design, Athos™ can be fully integrated into the wastewater treatment plant and provides continuous sludge processing, as well as by-product treatment.

Applications

Athos™ treats all types of thickened sludge :

- Primary

- Biological

- Fresh

- Digested

- Urban

- Industrial

References

P.E.: Population Equivalent

| Facility | Year | Capacity |

|---|---|---|

| Trucazzanno, Italy | 2004 | 300,000 PE |

| Epernay, France | 2006 | 80,000 PE |

| Brussels North, Belgium | 2008 |

1.2 Million PE |

| Aix-en-Provence, France | 2011 | 175,000 PE |

| Rennes Beaurade, France | 2012 | 360,000 PE |

Applications

With less than one-hour retention time in the reactor, the Athos™ process results in:

- Continuous and safe oxidation, under continuous mixing;

- High mineralization (less than 5% organic carbon content in the solid residue);

- Separation between liquid and mineral phases;

- Easily biodegradable liquid sidestream.

The heat released by the oxidation reaction is recovered to pre-heat the sludge, with no external energy supply.

Hydro-Thermal oxidation prototype: Athos™