With more than 50 years of experience, technologies and knowledge in desalination, we support municipalities and industries around the world in the implementation of their desalination strategies. From detailed process parameters to materials selection and technology implementation, we have developed cost-effective, efficient desalination solutions based on advanced technologies for the benefit of our customers.

Desalination allows converting seawater into a life sustaining and usable resource. Seawater covers 71% of the planet's surface and represents 97% of the world's water.

Seawater desalination is an increasingly key solution for scarcity of water guaranteeing water supply even in periods or areas of drought.

Seawater desalination plants offer numerous benefits to coastal communities in water-stressed regions:

- Augment and supplement available water sources with high-quality fresh water.

- Ensure a constant water supply during droughts or in desert environments.

- Eliminate the need to import fresh water from other locations.

Providing a reliable water supply through desalination

Desalination is an alternative solution to increase available water resources. In some regions of the world, it is the only source of water available.

Our specialized subsidiaries SIDEM and Entropie are recognized world leaders in both reverse osmosis and thermal desalination, providing expert services in design, engineering, procurement, construction, commissioning, operation and maintenance. We also offer standard desalination units and mobile water solutions that can be deployed on a temporary basis or in the face of emergency.

Flexibility

- Operation and maintenance flexibility.

- Compatible and complementary equipment.

Simplicity

- Global offer.

- Common water intake and brine discharge.

Unique offering on this segment

- Cost optimization.

- Low environmental impact.

Processes used for desalination

Reverse osmosis desalination

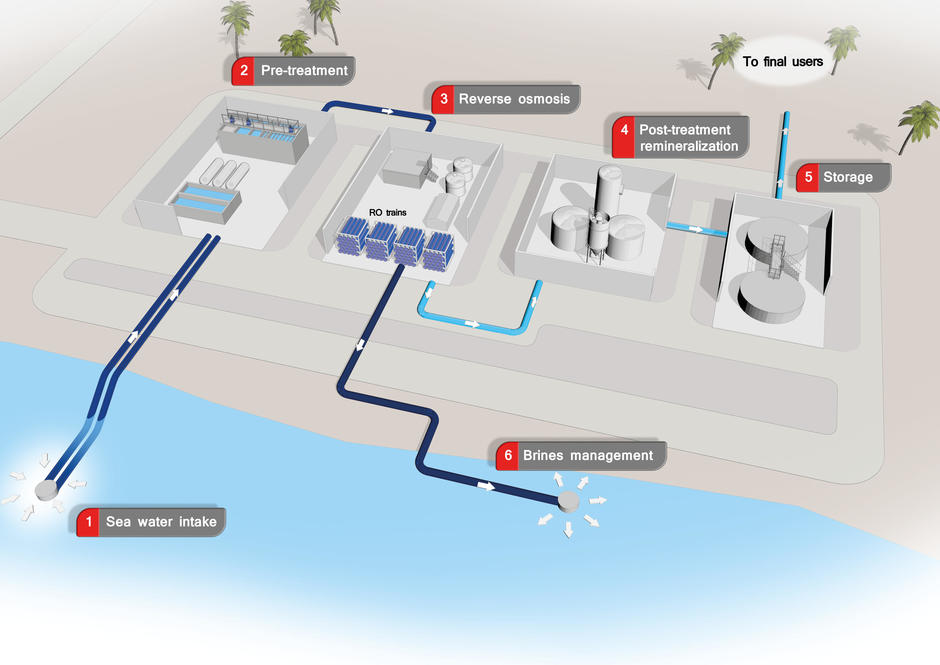

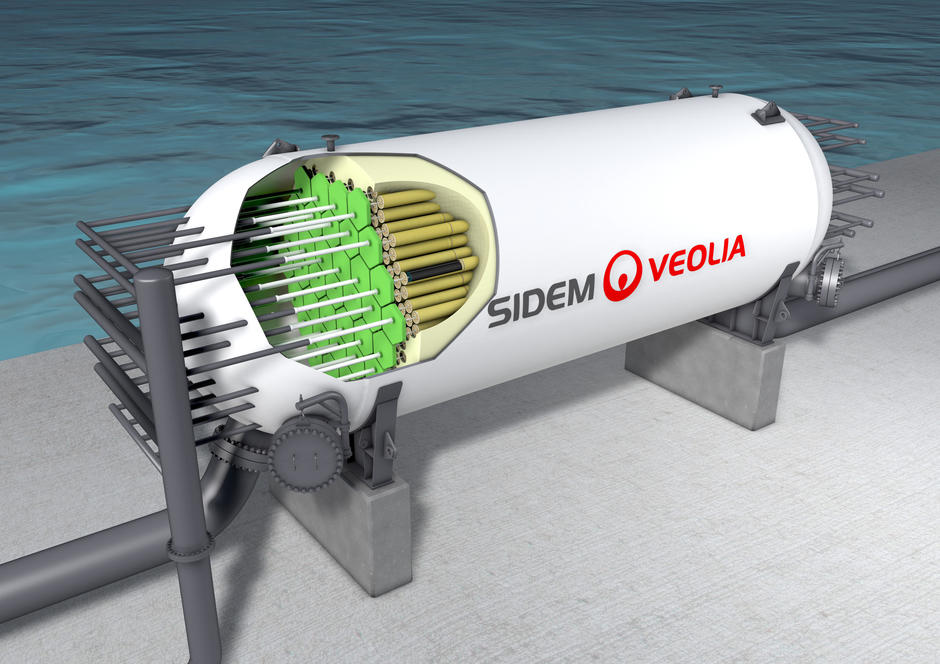

Reverse osmosis (RO) involves pushing water under pressure through a membrane which retains the salt and other impurities. Membrane separation processes are used for:

- Desalination of seawater.

- Production of process and potable water.

- Polishing and demineralization of boiler feedwater and pharmaceutical water.

- Rehabilitation and recycling of process and municipal effluent.

- As part of an integrated zero liquid discharge process.

Thermal water desalination

Thermal desalination processes are best applied to water and process streams with a high dissolved salt content, where the applied pressure required for an equivalent membrane system would be excessive.

The use of a low-cost energy source, such as the one available from cogeneration power plants, is advantageous with respect to reducing energy cost, if available. Another option is to use low-temperature, high-efficiency vacuum evaporation systems that can be operated on waste heat and a low electrical energy demand.

Hybrid systems

Hybrid systems combine both thermal and reverse osmosis technologies which, in some situations, can allow an optimization of water product costs.

Technological solutions for each stage of RO desalination

Recent breakthroughs in technologies and in process and plant monitoring have vastly improved the energy efficiency of desalination systems, allowing for a lower cost of water produced and a much improved environmental footprint.

Major advances in the pretreatment of raw water, which is indispensable to avoid damaging membranes, have also improved production costs and increased the efficiency and lifecycle of the membranes. Some of these advances include our Spidflow® DAF filter as well as our M&C filter, both of which help protect the membranes while allowing for a smaller footprint of SWRO plants.

Our latest innovation in RO technology is the Barrel™, a desalination system delivered on site as a ready-to-operate module. Safe, compact and digital, it meets the challenges and expectations of the desalinationmarket while producing fresh water compliant with all water quality standards.

Also suitable for water reuse and low-pressure reverse osmosis (LPRO) applications, the Barrel allows for significant savings in both capital and operating expenditures.

Creating value through smarter desalination technologies

We understand that membrane plant operators and managers face many challenges such as avoiding unplanned shutdowns and optimizing their plant’s maintenance schedule to save operator time and minimize downtime. Reverse osmosis systems can be very sensitive to changes in the operating environment, making it difficult for your operators to assess the real state of fouling and aging membranes.

In order to overcome these challenges, your operating team needs to correctly monitor the state of your system and anticipate possible deviations. With Smart Membranes, we combined our extensive process knowledge with artificial intelligence to normalize and predict the evolution of strategic operational parameters. We provide real-time and reliable assessments to confirm the fouling state of membranes to enable proactive and evidence-based decision making for your operating team.

Risk mitigation

Assess the fouling state of your membranes in real time to anticipate performance drifst and act in time to avoid unplanned shutdowns.

Proactivity

Optimize maintenance planning by using Smart Membranes predictive features.

Time optimization

Save time by accessing normalized data and indicators in real time.

Supporting municipal and industrial desalination

We have built hundreds of desalination plants and systems all over the world, producing freshwater for both municipal and industrial needs. Our most recent flagship projects include the Al Dur 2 plant in Bahrain, the Rabigh 3 plant in Saudi Arabia and the Umm Al Quwain IWP plant in UAE.

Since 2007, Veolia has built and operated the seawater reverse osmosis plant of Sur, together with the Oman Power and Water Procurement Company (OPWP). The partnership that Veolia has there with the Sharqiyah Desalination Company has allowed us to test and implement many innovations in terms of process development but also energy consumption and environmental footprint.

Sidem was contracted by Marafiq to design, supply, construct and commission a SWRO plant with ultrafiltration known as Jubail II. The project was commissioned in 2016 and is operated by Veolia since December 2016.

Our leading technologies help reduce water scarcity

Discover our water treatment technologies for desalination

Would you like more information about our technologies for desalination?

Processes to desalinate seawater and render it potable have been around for many decades but recent years have brought innovations that have greatly improved their energy consumption and environmental footprint. The oceans represent a fantastic resource for humanity, a vital one in water-scarce regions, and we are now able to capitalize on it in a more sustainable way.

Vincent Baujat

CEO SIDEM

Contact Vincent through his LinkedIn account

More services for our desalination clients

FAQ about desalination

How much water comes from desalination?

According to the International Desalination Association, the cumulative contracted desalination capacity has now surpassed 100 million m3/d. Roughly 60% of desalination is devoted to human consumption. It is estimated that some 300 million people rely on this process for their daily water usage.

Kuwait for instance has an average rainfall of 110mm per year and produces almost 100% of its fresh water use through desalination.

How long has seawater been desalinated?

The sun has done it forever ... by evaporation to provide rain.

Steam-powered ships were first equipped with evaporators for the production of boiler makeup water in the early 1900’s. Desalination units were first used on board ships and were then widely developed with the growth of OPEC countries (1970). The capacity of the plants has grown dramatically over that period, from a few hundreds cubic meters per day in the 1960's to hundreds of thousands of cubic meters per day for the largest desalination plants nowadays.

Does the quality of seawater have an impact on desalinated water?

Distillation processes are not sensitive to seawater quality. A 0.5mm filtration, chlorination and a suitable anti-scale and anti-foam treatment will be sufficient to guarantee a steady water quality versus time, particularly with the low temperature Multiple Effect Distillation (MED) process. Bacteria and pathogenic organisms are generally destroyed by these processes. Distilling pollutants are the only ones to create a problem when mixing with condensed vapor, if a seawater screening solution is not set up in due time.

Membrane processes are more sensitive to seawater quality. Depending on seasonal conditions, seawater quality may be affected by the weather or by biological activity. In such cases, pretreatment systems must be designed to withstand such conditions and prevent bio-fouling which is the clogging of membranes by bacteria.

Do desalination plants pollute?

Desalination plants reject slightly concentrated seawater called brine to the sea. The salt content of the brine is roughly 60g/l for seawater at 40g/l. The temperature of the brine reject is slightly higher than that of the seawater - a few degrees Celsius. This excess salt concentration and temperature quickly vanish in the vicinity of the rejection point.

Seawater is chlorinated at the plant inlet to avoid the growth of seaweed and seashells inside the piping. Chlorine is accurately dosed so as to avoid active chlorine remaining at the outlet of the plant.

Anti-scale and anti-foam additives are also dosed in seawater entering the plant, dose levels being in the range of a few grams per ton. Once they have reacted inside the plant and due to their huge dilution, they present no risk of pollution at the plant outlet.

Desalination units are often set in environmentally protected areas with no particular problem raised.

As such, a desalination plant has no other reject to the environment. However it can be coupled with a power plant. The rejects of such plants are controlled by environmental standards. These combined plants provide the best efficiency and minimise the overall impact of power and water production on the environment.

Technical resources

Find related content below. If you can’t find exactly what you are looking for, please contact us for further assistance.

Brochure

Videos