A microfiltration system for municipal and industrial wastewater treatment effluent to remove phosphorus and total suspended solids.

Overview

Nutrients, such as phosphorus, need to be removed in the wastewater treatment process as excessive levels in effluent can have detrimental environmental and public health impacts.

Likewise, solids and organic matter that are suspended in effluent leaving municipal wastewater treatment or industrial wastewater treatment works must also be removed.

Hydrotech Nutri-pack is a compact microfiltration package plant for pretreatment and water reuse, specifically designed to reduce nutrients, solids and organic matter suspended in effluent.

How does Hydrotech Nutri-pack work?

Hydrotech Nutri-pack is a dual chemical-physical tertiary treatment separation system that can reduce up to 90% of phosphorus and 95% of total suspended solids (TSS) in the effluent stream. Coagulation is used to precipitate phosphorus and polymer is added to floc the solids to improve microfiltration performance.

Chemical pretreatment systems are used by municipal wastewater treatment and industrial wastewater treatment facilities as a final processing stage to remove harmful pollutants before discharge to the environment. This process is usually used in a train with Hydrotech Discfilters or Hydrotech Drumfilters.

Hydrotech Nutri-pack is suitable for a range of applications and markets, including industrial and municipal wastewater treatment, food and beverage wastewater treatment, water reuse and groundwater treatment.

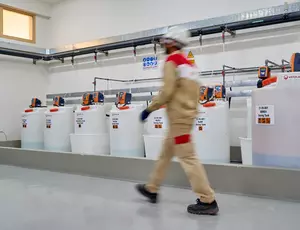

The system is pre-engineered and built at our dedicated factory in Sweden, which means short lead times and installation on site within 16 weeks of the order being placed. This includes factory acceptance testing (FAT) to ensure the mechanical and process systems are fully operational before arrival onsite.

The compact system is available in three standard sizes, for flow rates up to 120 cubic meter per hour (m3/h), and, where necessary, height customization is available to meet the hydraulic profile. These characteristics make Hydrotech Nutri-pack suitable for most small to medium-sized industrial and municipal wastewater treatment plants and fits into most existing facilities such as food and beverage wastewater treatment sites.

The Hydrotech Nutri-pack system includes a smart human-machine interface (HMI) control system, which has demonstrated a significant reduction in operating expenditure (OPEX), including chemical and maintenance savings. On-site testing showed a 40% reduction in polymer use and a 70% reduction in coagulants, compared with usual flow-proportional control.

The Hydrotech Nutri-pack integrates more than 20 years of design, commissioning and operational experience and capitalizes on our continuous innovation to meet your needs and reach outstanding performance.

Features and benefits

High treatment efficiency

Less than 90% phosphorus reduction, less than 95% TSS reduction.

Significant OPEX reduction

Through smart control panels and chemical savings.

Proprietary control system

Advanced instrumentation for robustness.

Quick delivery and start-up

Pre-site factory acceptance tests.

Standardized design

With optional enhancements and comprehensive documentation.

Applications

Services

Contact

Hydrotech™ Nutri-pack is an innovative solution that significantly reduces both phosphorus and suspended solids in wastewater. Its compact design, quick installation, and smart control system not only enhance treatment efficiency but also lead to substantial OPEX savings. This technology is a game-changer for small to medium-sized treatment plants looking to meet stringent environmental standards while optimizing their operations.

William Blandford

Development Department Manager

Contact William through his LinkedIn account

FAQ about Hydrotech™ Nutri-pack

In general, what is the role of phosphorus removal in wastewater treatment?

Phosphorus removal is a crucial step in the wastewater treatment process because excessive levels in wastewater effluent can have detrimental environmental and public health impacts. Phosphorus is a nutrient that, when present in excess in bodies of water, can lead to eutrophication.

This creates algal blooms, oxygen depletion, and loss of aquatic life. It reduces water clarity, disrupts ecosystems, and harms biodiversity. Algal toxins can also threaten human health, affecting drinking water supplies and recreational water quality, and posing environmental, economic and public health risks.

Is every phosphorous removal method the same?

No. The specific method chosen for phosphorus removal depends on the wastewater treatment plant's design, the local regulatory requirements, and the characteristics of the wastewater that needs to be treated. Effective phosphorus removal is essential to prevent environmental pollution, protect aquatic ecosystems, and ensure that treated wastewater meets regulatory standards before being discharged into natural water bodies.

What can wastewater treatment plant managers do to select the best microfiltration pre-treatment system for their needs?

Wastewater treatment plant managers should assess water quality, treatment goals, and regulatory requirements before selecting a microfiltration pre-treatment system. Key considerations include flow rate, pollutant load, and the type of contaminants (e.g., solids, oils or microorganisms).

Managers should also evaluate system efficiency, maintenance needs, energy consumption, and operational costs. Pilot testing the system under real conditions can provide valuable insights into performance. Compatibility with existing infrastructure and future scalability should also be considered.

Engaging with Veolia Water Technologies as equipment suppliers and industry experts can ensure an informed decision, leading to effective microfiltration, reduced downtime, and long-term cost savings.

Case Studies

As a producer of healthy and delicious dairy products, the customer wanted its wastewater treatment plant to prioritize safety over competitiveness. The wastewater recipient is a bordering creek to an international neighbor so exceeding discharge limits could lead to diplomatic challenges. Therefore, the effluent consent was very strict. A Hydrotech™ Nutri-pack was installed as part of the tertiary treatment of wastewater to help meet this consent.